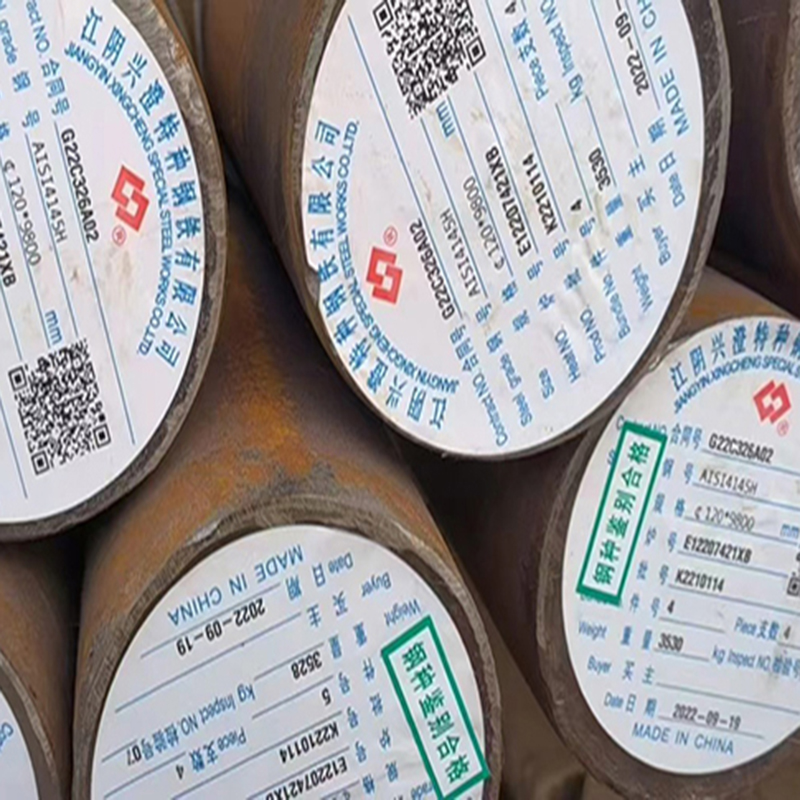

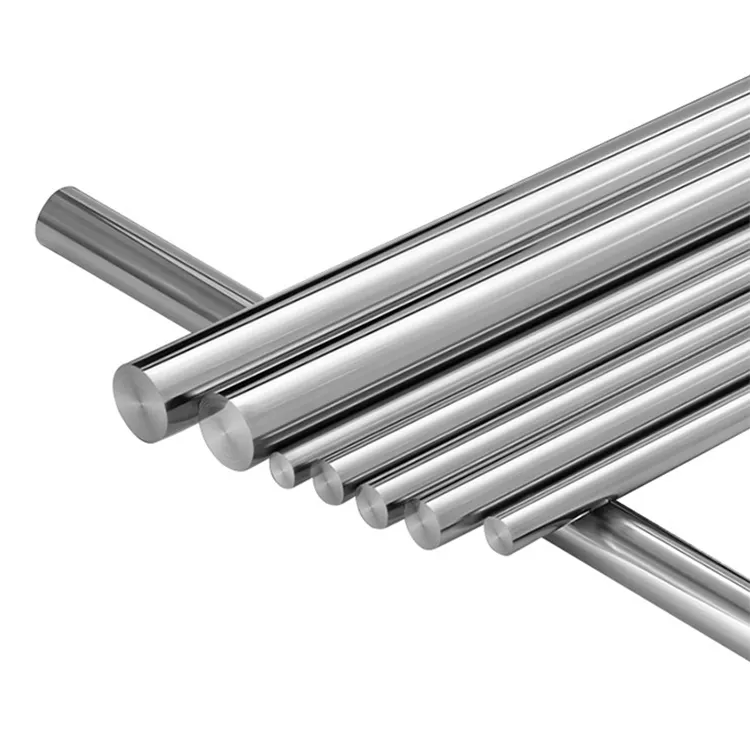

SAE4130 Steel Round Bar AISI 4130 Alloy Steel Bar

Re phehella tenet ea tsamaiso ea "Boleng bo ikhetha, Thuso e phahame ka ho fetisisa, Reputation ke ea pele", 'me re tla theha le ho arolelana katleho le bareki bohle ba SAE4130 Steel Round Bar AISI 4130 Alloy Steel Bar, Re boetse re tsoma ka ho tsoelang pele ho theha kamano le barekisi ba bacha ho fana ka mefuta e meng e tsoetseng pele le e bohlale ho bareki ba rona ba bohlokoa.

Re phehella molao oa tsamaiso oa "Boleng bo ikhethile, Thuso e phahame, Botumo ke ba pele", 'me re tla theha le ho arolelana katleho le bareki bohle bakeng saSebaka sa tšepe sa 4130, Re tšepa hore re ka theha tšebelisano ea nako e telele le bareki bohle.Mme re tšepa hore re ka ntlafatsa tlholisano mme ra fihlela maemo a win-win mmoho le bareki.Re amohela ka tieo bareki ba tsoang lefats'eng lohle ho ikopanya le rona bakeng sa eng kapa eng eo u e hlokang!

Likaroloana

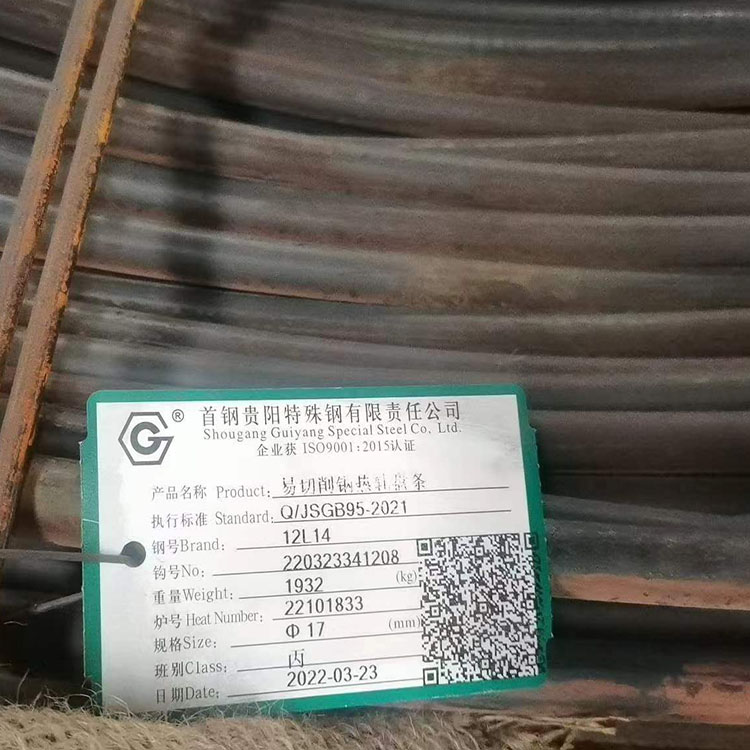

4130 4135 4140 4145H litšepe tsa tšepe ke tšepe e tlaase ea carbon alloy.Ke tsa alloy ea Chrome-Molly e nang le chromium le molybdenum e le lisebelisoa tse matlafatsang.

4130 round steel bar e na le bokhoni bo botle ba ho sebetsa, deformation e nyane ea ts'ebetso, le khanyetso e ntle ea mokhathala.Ke karolo ea tšepe ea matla a mahareng ho isa ho a phahameng.Ka mor'a phekolo ea mocheso, 4140 e na le matla a matle le thepa e feletseng ea mochine, bokhoni bo botle ba ts'ebetso, le chai e ngata.Mocheso oa tšebeletso ke likhato tse 427 tsa Celsius.

4140 e na le matla a phahameng, bokhoni bo thata, ho tiea, le deformation nakong ea ho tima.E na le matla a phahameng a ho hahaba le matla a ho mamella mocheso o phahameng.E sebelisetsoa ho etsa li-forging tse hlokang matla a phahameng le likarolo tse kholoanyane tse tingoeng le tse halefileng ho feta tšepe ea 4135, joalo ka likere tse kholo bakeng sa traction ea locomotive, booster transmission gears, back axles, connecting rods and spring clips tse imetsoeng haholo.

Tlhaloso

| Lebitso la Sehlahiswa | AISI ASTM 4130 4135 4140 Alloy Steel Bar | |

| Lintho tse bonahalang | ASTM | 4130,4135 4140,4145H |

| DIN | 1.7218 1.7225 1.7220 | |

| GB | 30CrMo 35CrMO 42CrMo | |

| Standard | GB/T799, ASTM A29, A108, A321, A575, BS970, DIN1652, JIS G4051 | |

| OD | 6mm ho isa ho 600mm | |

| Bokaholimo | E pentiloeng ka botšo, e Bare, e hloekisitsoe, e pentiloe ka Chrome | |

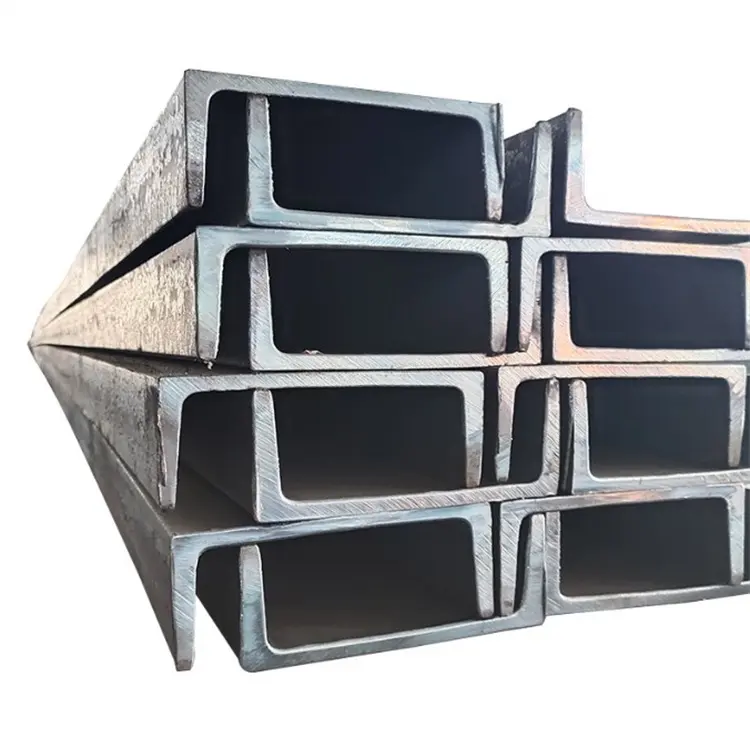

| Litlhaloso | Sebaka se chitja | 8mm ~ 800mm |

| Angle bar | 3mm*20mm*20mm~12mm*800mm*800mm | |

| Square bar | 4mm * 4mm ~ 100mm * 100mm | |

| Flat bar | 2 * 10mm ~ 100 * 500mm | |

| Hexagonal | 4mm ~ 800mm | |

| Tshebetso | Sebōpi sa motlakase se ile sa qhibiliha, sa qhekelloa 'me sa kenngoa, se pota-potile. | |

| Ho thatafala: | HBS 217Max (E fapane le kalafo ea mocheso) | |

| Tlhahlobo ea UT | SEP 1921/84/2 sehlopha sa C/c. | |

| Mamello | Dia -0/+ 0~5mm, Botenya -0/+ 0~5mm, Bophara: -0/+ 0~10mm. | |

| Bolelele | 2m, 4m, 5.8m, 6m, 11.8m, 12m kapa ha ho hlokahala. | |

| Sephutheloana | Ho paka ka Leoatleng. | |

| Equal different standard | |||

| AISI | GB | DIN | JIS |

| 4130 | 30CrMo | 1.7218 | SCM420 |

| 4140 | 42CrMo | 1.7225 (42CrMo4) | SCM440 |

| 4135 | 35Crmo | 1.7220 (34CrMo4) | SCM432 |

| 4145H | - | - | - |

Sebopeho sa Lik'hemik'hale

| Sebopeho sa Lik'hemik'hale (%) | |||||||

| Kereiti | C | Si | Mn | P | S | Cr | Mo |

| 4130 | 0.28-0.33 | 0.15-0,35 | 0.40-0,60 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0,25 |

| 4140 | 0.38-0.43 | 0.15-0,35 | 0.75-1.0 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0,25 |

| 4135 | 0.33-0.38 | 0.15-0,35 | 0.75-0.9 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0,25 |

| 4145 | 0.43-0.48 | 0.15-0,35 | 0.75-1.0 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0,25 |

Thepa ea Mechini

| Litšobotsi: |

| 1.Low alloy steel e nang le molybdenum le chromium e le lisebelisoa tse matlafatsang; |

| 2.E babatsehang ho tloha boemong ba fusion weldability; |

| 3.The alloy e ka thatafatsoa ke phekolo ea mocheso. |

Mamello

| Boemo ba Phano |

| 1.Hot rolled |

| 2.E hlakotsoe |

| 3.E tloaelehileng |

| 4. Koala le ho halefa |

Maemo a phekolo ea mocheso

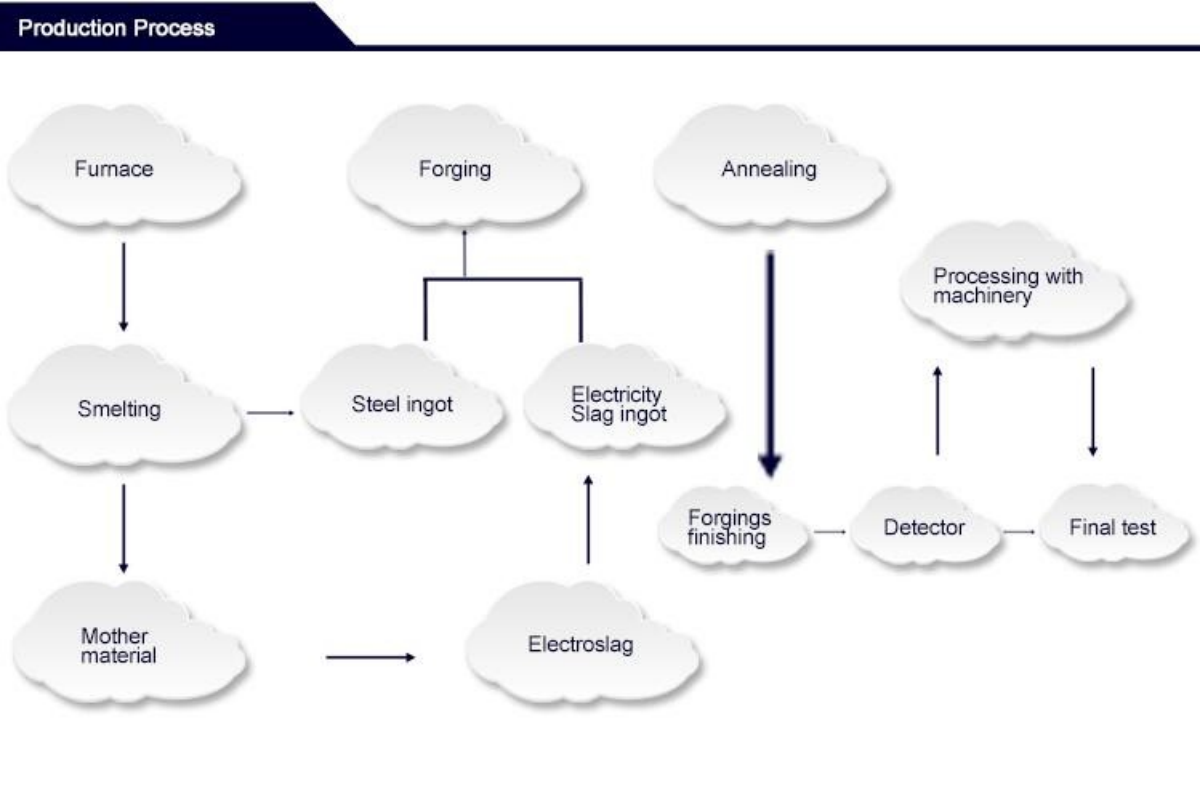

1.Annealing: 880℃ Pholiso ea sebōpi

2.Normalization: 880 ~ 870℃ moea o pholisoe

3.Ho thatafatsa: 820 ~ 870℃ Pholiso ea metsi

4.Tempering: 550 ~ 650℃ Pholiso e potlakileng

Thepa ea Mechanical e ka fumanoa ka kalafo e fapaneng ea mocheso.

Sephutheloana

1.Ka mekotla, boima bo bong le bo bong bo ka tlase ho lithane tse 3, bakeng sa kantle ho tse nyane

bophara ba bar e chitja, ngata e 'ngoe le e 'ngoe e nang le likhoele tsa tšepe tse 4 - 8.

Setshelo sa maoto a 2.20 se na le boholo, bolelele bo ka tlase ho 6000mm

Setshelo sa maoto a 3.40 se na le boholo, bolelele bo ka tlase ho 12000mm

4.Ka sekepe se seholo, Tefiso ea thepa e tlase ka thepa e ngata, ebile e kholo

saese e boima e ke ke ea laeloa ka har'a linkho tse tsamaisoang ka thepa e ngata

Netefaletso ea boleng

1.E thata ho latela Litlhoko

2. Mohlala: Mohlala oa fumaneha.

3. Liteko: Teko ea ho fafatsa letsoai / Teko ea Tensile / Eddy hajoale / Teko ea sebopeho sa lik'hemik'hale ho latela kopo ea bareki

4.Certificate: IATF16949, ISO9001, SGS joalo-joalo.

5. EN 10204 3.1 Setifikeiti

SAE4130 tšepe e chitja ke tšepe ea theko ea alloy.Tloaelo ea ASTMA29/A29M-04.Letšoao le ts'oanang la lehae: 30CrMo Letšoao le Tšoanang la Majapane: SCM430 (SCM2) Letšoao le Tšoanang la Sejeremane: 34CrMo4 (1.7220)

4130 tšepe ea mohaho e na le matla a phahameng le ho tiea, ho thatafala ho phahameng, le bophara bo boima ba boima ba 15-70mm ka oli;Matla a mocheso a tšepe a boetse a ntle, ka matla a lekaneng a mocheso o phahameng ka tlase ho 500 ℃, empa matla a eona a fokotseha haholo ho 550 ℃;Ha motsoako oa motsoako o le moeling o ka tlase, welding e ntle haholo, empa ha e le haufi le moeli o ka holimo, weldability e bohareng, 'me preheating ho ea holimo ho 175 ℃ e hlokahalang pele ho tjheseletsa;Tšepe e na le machinability e ntle le polasetiki e itekanetseng nakong ea deformation e batang;Nakong ea phekolo ea mocheso, ho na le brittleness e tšoanang ea bohale ka har'a 300-350 ℃;Ho na le tšekamelo ea ho theha matheba a masoeu.

SAE4130 e sebelisoa haholo indastering ea tlhahiso ea mechine e mahareng ho etsa likarolo tse tingoeng le tse halefileng tse nang le likarolo tse kholo tse fapaneng tse sebetsang tlas'a maemo a khatello ea maikutlo, joalo ka li-shafts, spindles, le mabili a phahameng a laolang mojaro, liboutu, liboutu tsa hlooho tse peli, likere. joalo-joalo;E sebelisoa indastering ea lik'hemik'hale ho etsa likarolo tse cheselitsoeng, meaho e cheselitsoeng e entsoeng ka lipoleiti le liphaephe, le liphaephe tse phahameng tsa khatello tse nang le mocheso o sa feteng 250 ℃ tse sebetsang ka mokhoa o nang le naetrojene le hydrogen;Ka indasteri ea tlhahiso ea li-turbine tsa mouoane le li-boilers, e sebelisoa ho etsa li-fasteners bakeng sa mosebetsi o ka tlase ho 450 ℃, li-flange le likoahelo tsa flange tlas'a khatello e phahameng e ka tlase ho 500 ℃.