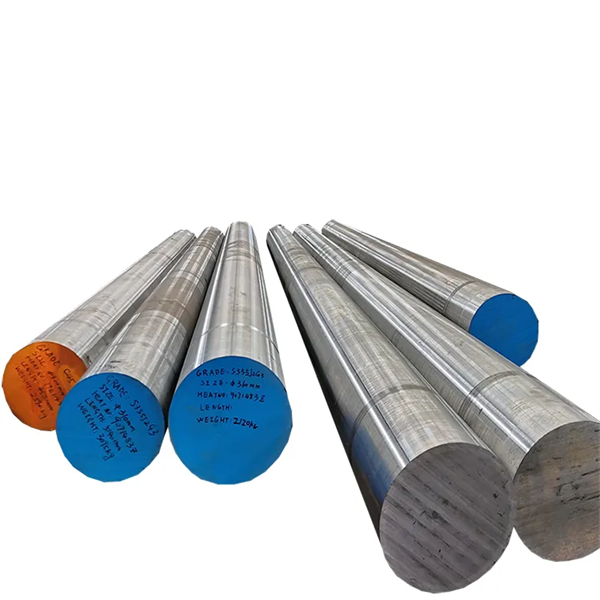

AISI SAE 4130 4140 4145H Steel Round Bar Hollow Rod

Likaroloana

4130 4135 4140 4145H litšepe tsa tšepe ke tšepe e tlaase ea carbon alloy.Ke tsa alloy ea Chrome-Molly e nang le chromium le molybdenum e le lisebelisoa tse matlafatsang.

4130 round steel bar e na le bokhoni bo botle ba ho sebetsa, deformation e nyane ea ts'ebetso, le khanyetso e ntle ea mokhathala.Ke karolo ea tšepe ea matla a mahareng ho isa ho a phahameng.Ka mor'a phekolo ea mocheso, 4140 e na le matla a matle le thepa e feletseng ea mochine, bokhoni bo botle ba ts'ebetso, le chai e ngata.Mocheso oa tšebeletso ke likhato tse 427 tsa Celsius.

4140 e na le matla a phahameng, bokhoni bo thata, ho tiea, le deformation nakong ea ho tima.E na le matla a phahameng a ho hahaba le matla a ho mamella mocheso o phahameng.E sebelisetsoa ho etsa li-forging tse hlokang matla a phahameng le likarolo tse kholoanyane tse tingoeng le tse halefileng ho feta tšepe ea 4135, joalo ka likere tse kholo bakeng sa ho tsamaisa li-locomotive traction, booster transmission gears, li-axle tse ka morao, lithupa tse hokelang le likotoana tsa selemo tse imetsoeng haholo.

Tlhaloso

| Lebitso la Sehlahiswa | AISI ASTM 4130 4135 4140 Alloy Steel Bar | |

| Lintho tse bonahalang | ASTM | 4130,4135 4140,4145H |

| DIN | 1.7218 1.7225 1.7220 | |

| GB | 30CrMo 35CrMO 42CrMo | |

| Standard | GB/T799, ASTM A29, A108, A321, A575, BS970, DIN1652, JIS G4051 | |

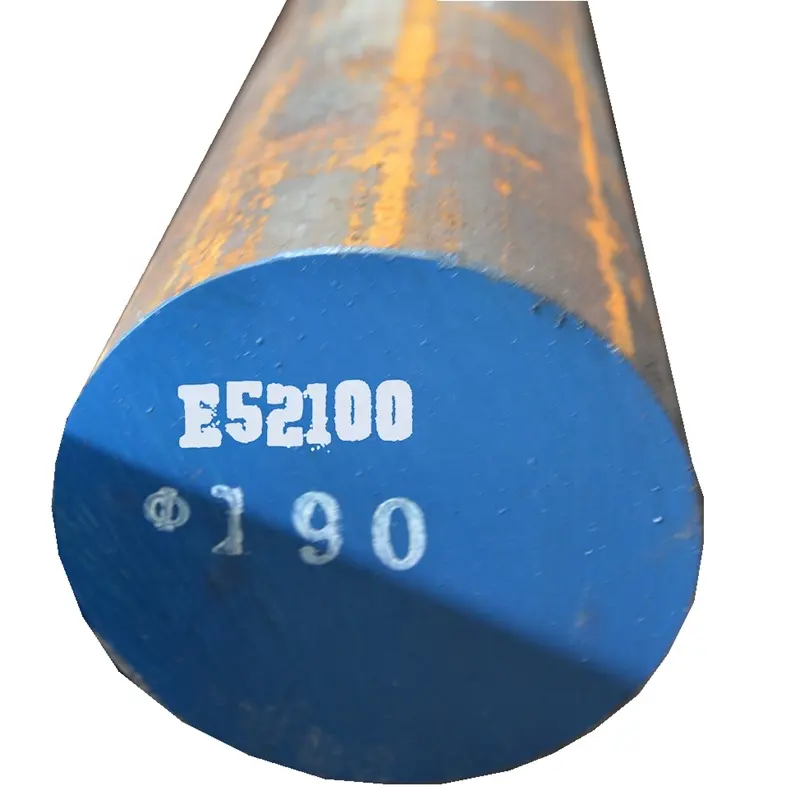

| OD | 6mm ho isa ho 600mm | |

| Bokaholimo | E pentiloeng ka botšo, e Bare, e hloekisitsoe, e pentiloe ka Chrome | |

| Litlhaloso | Sebaka se chitja | 8mm ~ 800mm |

| Angle bar | 3mm*20mm*20mm~12mm*800mm*800mm | |

| Square bar | 4mm * 4mm ~ 100mm * 100mm | |

| Flat bar | 2 * 10mm ~ 100 * 500mm | |

| Hexagonal | 4mm ~ 800mm | |

| Tshebetso | Sebōpi sa motlakase se ile sa qhibiliha, sa qhekelloa 'me sa kenngoa, se pota-potile. | |

| Ho thatafala: | HBS 217Max (E fapane le kalafo ea mocheso) | |

| Tlhahlobo ea UT | SEP 1921/84/2 sehlopha sa C/c. | |

| Mamello | Dia -0/+ 0~5mm, Botenya -0/+ 0~5mm, Bophara: -0/+ 0~10mm. | |

| Bolelele | 2m, 4m, 5.8m, 6m, 11.8m, 12m kapa ha ho hlokahala. | |

| Sephutheloana | Ho paka ka Leoatleng. | |

| Equal different standard | |||

| AISI | GB | DIN | JIS |

| 4130 | 30CrMo | 1.7218 | SCM420 |

| 4140 | 42CrMo | 1.7225 (42CrMo4) | SCM440 |

| 4135 | 35Crmo | 1.7220 (34CrMo4) | SCM432 |

| 4145H | - | - | - |

Sebopeho sa Lik'hemik'hale

| Sebopeho sa Lik'hemik'hale (%) | |||||||

| Kereiti | C | Si | Mn | P | S | Cr | Mo |

| 4130 | 0.28-0.33 | 0.15-0,35 | 0.40-0,60 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

| 4140 | 0.38-0.43 | 0.15-0,35 | 0.75-1.0 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

| 4135 | 0.33-0.38 | 0.15-0,35 | 0.75-0.9 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

| 4145 | 0.43-0.48 | 0.15-0,35 | 0.75-1.0 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

Thepa ea Mechini

| Litšobotsi: |

| 1.Low alloy steel e nang le molybdenum le chromium e le lisebelisoa tse matlafatsang; |

| 2.E babatsehang ho tloha boemong ba fusion weldability; |

| 3.The alloy e ka thatafatsoa ke phekolo ea mocheso. |

Mamello

| Boemo ba Phano |

| 1.Hot rolled |

| 2.E hlakotsoe |

| 3.E tloaelehileng |

| 4. Koala le ho halefa |

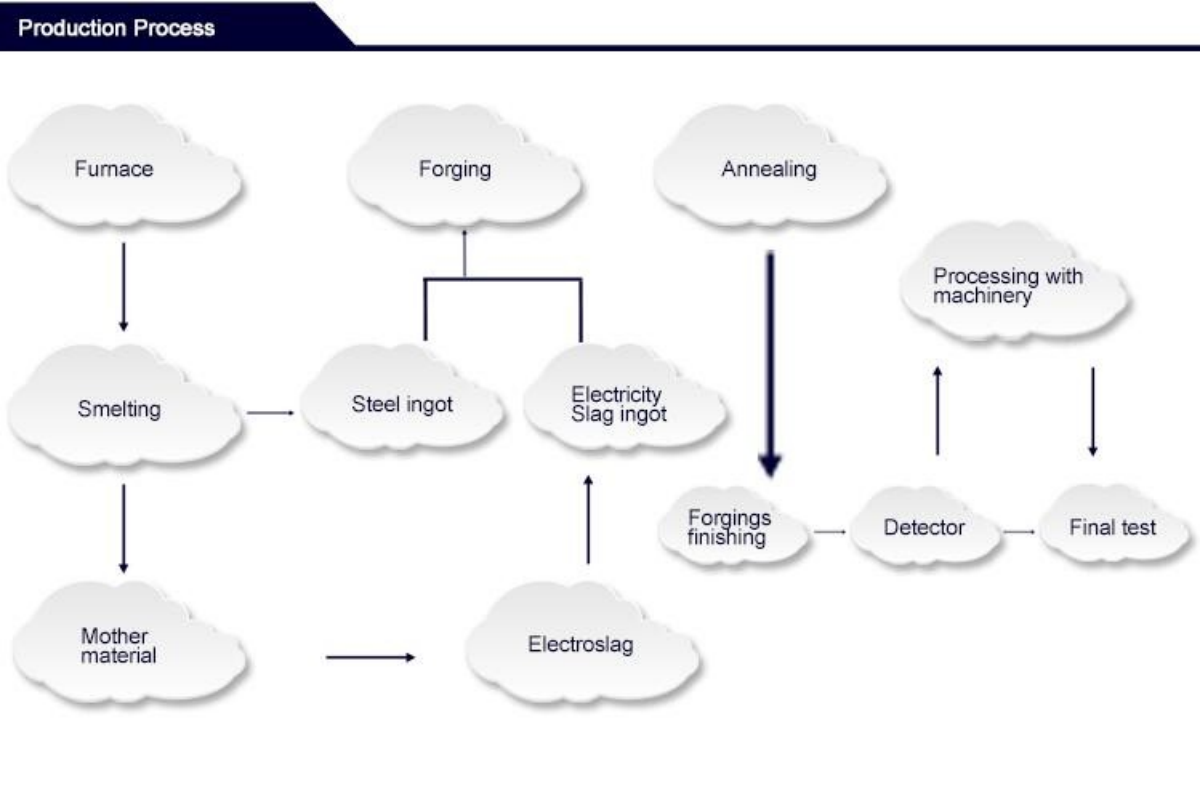

Maemo a phekolo ea mocheso

1.Annealing: 880℃ Pholiso ea sebōpi

2.Normalization: 880 ~ 870℃ moea o pholisoe

3.Ho thatafatsa: 820 ~ 870℃ Pholiso ea metsi

4.Tempering: 550 ~ 650℃ Pholiso e potlakileng

Thepa ea Mechanical e ka fumanoa ka kalafo e fapaneng ea mocheso.

Sephutheloana

1.Ka mekotla, boima bo bong le bo bong bo ka tlase ho lithane tse 3, bakeng sa kantle ho tse nyane

bophara ba bar e chitja, sephutheloana se seng le se seng se nang le likhoele tsa tšepe tse 4 - 8.

Setshelo sa maoto a 2.20 se na le boholo, bolelele bo ka tlase ho 6000mm

Setshelo sa maoto a 3.40 se na le boholo, bolelele bo ka tlase ho 12000mm

4.Ka sekepe se seholo, Tefiso ea thepa e tlase ka thepa e ngata, ebile e kholo

saese e boima e ke ke ea laeloa ka har'a linkho tse tsamaisoang ka thepa e ngata

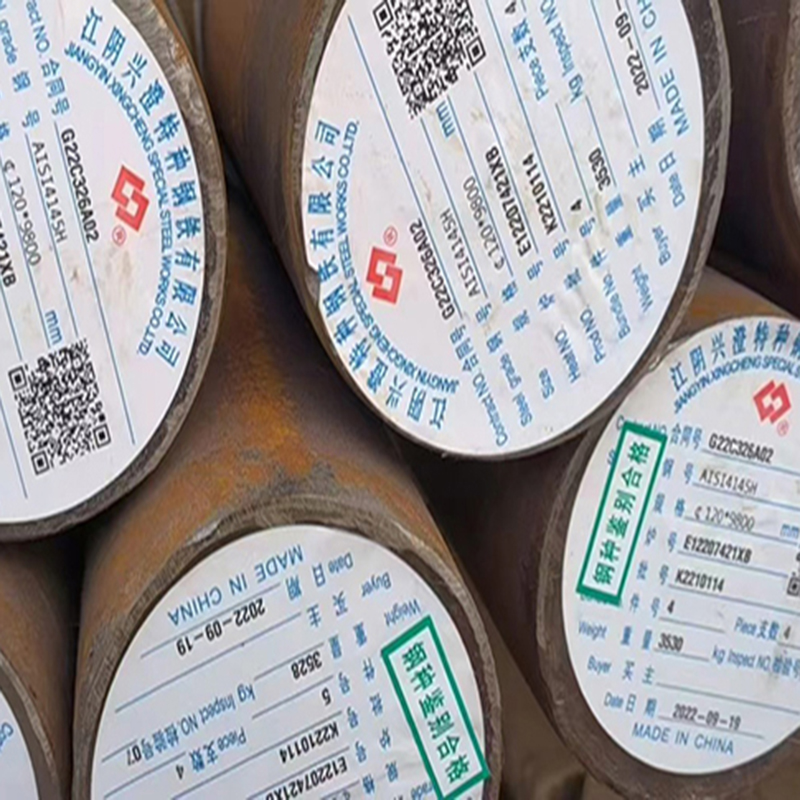

Netefaletso ea boleng

1.E thata ho latela Litlhoko

2. Mohlala: Mohlala oa fumaneha.

3. Liteko: Teko ea ho fafatsa letsoai / Teko ea Tensile / Eddy hajoale / Teko ea sebopeho sa lik'hemik'hale ho latela kopo ea bareki

4.Certificate: IATF16949, ISO9001, SGS joalo-joalo.

5. EN 10204 3.1 Setifikeiti